Climate Action and Biodiversity

Vision

50% absolute reduction in CO2 emissions by 2027 based on a 2021 baseline*

Directly invest in the local environment of GANNI’s suppliers to promote biodiversity by 2025

In 2023, climate action remained one of our primary focuses at GANNI. With our new GAMEPLAN 2.0 strategy, we continue to map and measure our carbon footprint, opting for proven lower-carbon alternative materials and intensifying our focus on decarbonisation through our 7 by 27 strategy (more on that later!). Additionally, we're concentrating on carbon insetting, involving direct investments and collaboration with our supply chain. This includes implementing solar panels on factory roofs to reduce emissions. We've also initiated biodiversity projects with our manufacturers to enhance the wildlife and biodiversity around the factories. However, we're exploring ways to scale up such initiatives. In 2023, this work permeated GANNI, thanks to the efforts of our Carbon Squad.

*Our 2027 decarbonisation goal and 7 by 27 strategy have been third-party verified by our carbon accounting partner, Plan A.

The Scientific Stuff

Scopes Explained

SCOPE 1

Direct emissions from owned or controlled sources. e.g. stores, offices

SCOPE 2

Indirect emissions from the generation of purchased energy

Scope 3

Indirect emissions (not included in scope 2) that occur in the value chain of the reporting company, including both upstream and downstream emissions

In 2022, our emissions across scopes 1, 2, and 3 experienced a notable rise, marking a 16% increase from our 2021 baseline, reaching a total of 19,061.17 tCO2e. Much of this increase can be attributed to expanding our operations into additional locations, including China, which internationalised our supply chain and necessitated an increase in transportation logistics. Simultaneously, our business travel increased as it was the first year with unrestricted travel since the Covid-19 pandemic. On the other hand, we celebrated a reduction in the footprint of our used materials, which was lowered by 2% despite the total purchased volume in kg increased by 14%. While this reduction may seem marginal, materials constituted roughly half of our total carbon footprint then, making emissions reduction in this category a great focus for us. This reduction reassured us of our commitment to preferred and innovative, low-emission materials over conventional ones. Similarly, the emission intensity of our packaging decreased as we opted for recycled content for all of our polybags.

In 2023, our emissions across scopes 1, 2 and 3 amounted to 15,514.88 tCO2e, resulting in a 20% reduction compared to last year, and a 7% decrease to our 2021 baseline. The overall positive result was achieved thanks to a combination of factors. Firstly, the carbon footprint for our purchased materials dipped below 2022 and 2021 levels. Since materials constituted almost 60% of our total carbon footprint in 2023, reductions in this area can significantly influence our overall impact. Additionally, we achieved a decline in both upstream and downstream transportation, a change made possible not only by our decarbonisation efforts but also by our commitment to collect more granular data allowing for a more detailed analysis of our environmental impact. For example, in 2023, we tracked more detailed information about our transportation and distribution processes, leading to methodological

improvements and more accurate results. Last but not least, we're glad to share that emissions related to the use phase of our garments have decreased. Similar to the above, this progress owes some credit to the finer details in our data, which refined our calculation methodology and eliminated some of the assumptions used in previous years.

Overall, 2023 reassured us of our commitment to our ‘Preferred’ materials strategy and underscored the importance of detailed data in our decarbonisation journey. Granular data not only enables the use of more accurate methodologies but also reduces the need for assumptions to fill in data gaps persistent in the fashion industry. Most importantly, detailed data enhances our understanding of our operations and helps us identify emission-heavy business categories. This, in turn, equips us to make evidence-based decisions and sheds light on our next decarbonisation projects. Moving forward, we will remain committed to improving our data to make better choices every day and work towards our goal of reducing our absolute emissions by 50% by 2027.

Overview of 2023 CCF

Scope 1: 0 tCO2e*

Scope 2: 475.68 tCO2e

Scope 3: 15,039.20 tCO2e

Overview of 2023 CCF

Scope 1: 3.39 tCO2e*

Scope 2: 253.88 tCO2e

Scope 3: 19,061.17 tCO2e

Overview of 2023 CCF

Scope 1: 2.55 tCO2e*

Scope 2: 216.68 tCO2e

Scope 3: 16,386.25 tCO2e

* In previous years, our heating emissions were classified under Scope 1, which accounts for direct emissions from owned or controlled sources. However, due to improved access to information on our heating systems used across GANNI stores and offices, as well as improved calculation methods that both reflect district heating, we reclassified our heating emissions from Scope 1 to Scope 2. Scope 2 encompasses indirect emissions from purchased electricity, heat, or steam. This shift reflects a more accurate understanding of our emissions profile, as we now account for the emissions associated with district heating production rather than making assumptions about on-site stationary combustion.

Decarbonisation

GOAL 1

Launch GANNI’s 7 by 2027 plan to reduce carbon emissions 50% by 2027

GANNI has committed to a very ambitious 50% absolute reduction in carbon emissions by 2027, from a 2021 baseline. This is a pretty outlandish goal for a company that is still growing. Still, it's extremely important for us to rally around a moonshot goal and do our absolute best to make it a reality because it’s what is needed and necessary to reach the 1.5 degree target set out in the Paris Agreement. We won’t achieve this goal alone; we are heavily reliant on legislation, research, data and systemic level change. We also can’t wait around for this to be in place, so we need to get creative and work with what we have.

Thinking outside the box, in 2022, we developed the 7 by 27 strategy, which encompasses seven key focus areas. We believe that by centring our efforts on these 7 workstreams, we have a real chance of achieving the 50% absolute reduction goal.

7 By 27

In 2023, we assembled a Carbon Squad comprised of individual working groups for each of the 7 by 27 workstreams. Within these groups, we deep-dived into the emission reduction potential of each focus area, initiating the process of charting decarbonisation pathways and identifying key leverage points.

Progress in 2023 includes:

- Hosted our very first Learning & Development Day for the 19 Carbon Squad members across the organisation to boost their knowledge on decarbonisation and to pair them with experts and innovators working in the space.

- Updated our criteria for ‘Preferred’ materials and identified 11 Fabrics of the Future that we believe have the biggest potential for commercialisation in 2024.

- Devised a transportation strategy for 2024, which acknowledges current challenges within the supply chain including the circumstances around the Red Sea Conflict, but works around what is possible in the short term versus where we want to be in the long term. To reduce the environmental footprint of our inbound transportation, we have developed a pilot project that prioritises sea freight over air freight for certain product categories on the most emission-intensive transportation routes, such as from Portugal to the US. In 2024, we are actively working on implementing this pilot, which involves optimising processes ranging from business forecasting and wholesale operations to supply chain planning and engagement with transportation suppliers.

- Assessed the impact of our first carbon insetting and biodiversity projects at our supplier, Ramil (Portugal), resulting in direct emission savings of 5.3 tCO2e. We finalised the installation of biodiversity measures at our 2nd supplier onboarded to the project, Rodrigues (Portugal). We completed the installation of solar panels with our 3rd supplier, Matex (Italy).

In 2024, we need to break down the overall 50% reduction goal into smaller bitesize targets for each of the 7 by 27 workstreams to ensure we progress towards our overarching goal. To do this, we will work closely with our carbon consultants and internal teams to determine targets that are both ambitious and feasible.

The 7 by 27 Workstreams

1. Materials & innovation

Using preferred materials & Fabrics of the Future

2. Climate action awareness

Creating internal & external awareness campaigns

3. renewable energy

Ensuring the use of renewable energy in stores & offices

4. Circularity

Designing for circularity, circular business models, increasing recycling & upcycling

5. Transportation

Decreasing emissions in inbound, outbound & last mile delivery

6. Insetting

Investing directly in our supply chain to reduce carbon emissions

7. No coal

Removing the use of coal in our supply chain

GOAL 2

Develop and roll out a carbon removal scheme for unavoidable scope 1 & 2 emissions in 2023

In 2023, implementing a carbon removal scheme wasn't a priority for us, and the same holds for 2024. Our primary commitment remains directed towards reducing our emissions and decarbonising our value chain, aligning with our goal of achieving a 50% absolute emission reduction by 2027, based on a 2021 baseline. As we progress, we will explore and introduce carbon removal schemes specifically for the emissions we find challenging to decrease or avoid.

GOAL 3

Commit to not working with Tier 1-2 suppliers that use coal-generated heat or energy by 2025

During 2023, we worked with Fairly Made, our Traceability partner, to try and obtain concrete, evidence-based information on coal use in our supply chain. We initially targeted India and China, as these countries are considered high coal-using countries. During our investigation, none of GANNI’s contractual suppliers were found to be using coal. However, we need to examine the practices further down the supply chain, especially at the Tier 2 supplier level. These suppliers often manage wet processes like dyeing, which requires substantial amounts of water and high temperatures to effectively bond the dye with fabric fibres. To accomplish this, many facilities rely on boilers to generate steam, which is crucial for heating water in dyeing baths and maintaining stable temperatures throughout the dyeing process. In such scenarios, coal-fired boilers can be a common choice for generating steam.

In 2024, we are expanding our investigation to look across our global supply chain and look forward to having more visibility on coal use in the spring and summer. From there, we aim to identify and implement coal removal strategies and projects. However, this work is complex, and if we are to find coal usage in the supply chain, GANNI alone may not have enough leverage to transition coal-reliant manufacturing to an alternative method. However, we remain focused on obtaining as much primary data as possible and will go from there, committed to finding less environmentally straining ways forward.

Spotlight on Carbon Squad

In last year's report we announced our intent to create a CARBON SQUAD, made up of 19 employees from across the business who are actively working on our decarbonisation strategy, known as the 7 by 27.

The 19 GANNI employees work in different departments including Logistics, Marketing, HR and Merchandising which is extremely important, because they are experts in their respective fields, meaning that expertise does not need to be housed within the sustainability team.

Official Carbon Squad Kick-off

Full Carbon Squad meeting setting direction for the group for 2023

Learning and Development Day with guest speakers Plan A, Seasony, and Damn Good Coffee

The Carbon Squad hosts two COP28 themed breakfasts for GANNI in collaboration with the Global Fashion Agenda

Data collection kick-off to measure our 2023 Carbon Footprint with a deeper focus on decarbonisation potential

Carbon Insetting

GOAL 4

Scale and evolve carbon insetting to 5 more suppliers by 2025

Solar panels were installed with Ramil (Portugal), one of our organic cotton T-shirt suppliers

Solar panels installed at Matex (Italy), one of GANNI’s knitwear suppliers. This is the first time we have collaborated on the installation of solar panels with a Tier 2 manufacturer

Biodiversity results were gathered on the progress at Ramil (Portugal) by our biodiversity consultants, STRIX

Solar panels installed at a third supplier, Rodrigues (Portugal), GANNI’s printed t-shirt and jersey suppliers

Solar panels installed at FMF (Italy), one of GANNI’s knitwear suppliers

Carbon Consultants, Plan A, measured the emission savings of the solar panels at Ramil (Portugal) for 2023 and found overall emission savings of 10 tCO2e in a 1 year monitoring period

By January 2024, we successfully installed solar panels at 4 of our manufacturing sites in close collaboration with our suppliers Ramil (Portugal), Rodrigues (Portugal), Matex (Italy) and FMF (Italy). A huge thank you to these suppliers who have willingly gone on this journey with GANNI in the hopes of reducing carbon emissions and for letting us monitor and measure the energy activity at these factories!

Results

The full-year results from Ramil (Portugal) for the period January 2023-December 2023 have shown the following:

- In comparison to a modelled scenario without solar panels, the pilot project resulted in direct emissions savings of 5,3 tCO2e

- Due to a lack of battery storing the solar energy for later use, the unused energy was sent back to the grid, resulting in additional indirect emission savings of 4,7 tCO2e

- In total, in comparison to a modelled scenario without solar panels, the pilot project resulted in overall emissions savings of 10 tCO2e

During the monitoring period from January to December 2023, Ramil's emissions for purchased energy totalled 7.8 tCO2e. With 41% of the electricity sourced from solar panels, Ramil reduced its grid energy consumption, resulting in direct emission savings of 5.3 tCO2e. In a hypothetical scenario without solar panels, emissions would have risen to 13,1 tCO2e. Ramil's excess energy sent back to the grid led to additional indirect emission savings of 4.7 tCO2e, bringing the overall emission savings to 10 tCO2e.

If Ramil had installed a battery storage system throughout 2023, they could have potentially operated as 'Net Zero' for 5 months of the year, from April to August. During these months, excess energy generated during peak production periods could have been stored in the battery and used to meet the factory's energy demand when solar energy production was lower, resulting in minimal reliance on grid electricity. In this hypothetical scenario, Ramil’s total emissions from energy used would have been lowered to only 3,1 tCO2e.

What does this mean?

By financially supporting the installation of solar panels at Ramil’s factory, GANNI contributed to a decrease in Ramil’s Scope 2 emissions (indirect emissions from the generation of purchased energy).

What does this mean for GANNI?

This implies that products manufactured at Ramil's factory were partially made with renewable energy, decreasing GANNI's Scope 3 emissions (all indirect emissions (not included in Scope 2) that occur in the value chain of the reporting company, including both upstream and downstream emissions). However, the methodological infrastructure doesn't recognise these emission savings as part of our absolute carbon reduction of 7%, which is often the case when working with such novel innovations.

Even though we cannot see the emission savings depicted above reflected in our absolute emissions, the carbon insetting project directly impacted Ramil’s Scope 2 emissions, resulting in the factory using 41% less energy from the grid! This proves a strong business case for the continued rollout of Carbon Insetting through the solar panels initiative. Currently, four of our suppliers, two based in Portugal and two in Italy, are enrolled in the project. Our goal is to extend this effort further and onboard three more suppliers by the end of 2025. We’re looking forward to sharing our progress and additional emission savings in our 2024 report!

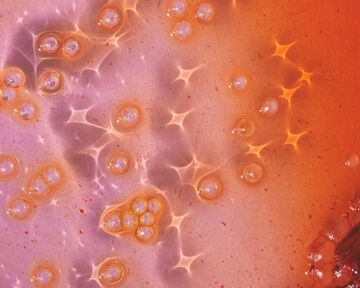

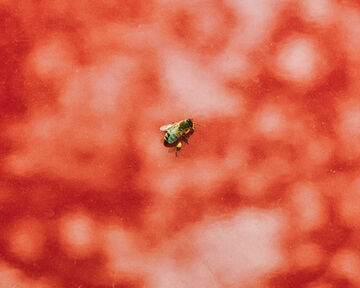

Biodiversity

GOAL 5

Pilot 2 measurable biodiversity projects in Portugal by 2023

Biodiversity measures were implemented on the surrounding site of Ramil’s factory by GANNI’s Biodiversity Consultants, STRIX (see last year’s Responsibility Report for a full breakdown of what we did)

STRIX performed a biodiversity impact assessment at Ramil to measure the improvement of biodiversity in the area

Carbon Consultants, Plan A, measured the emission savings of the solar panels at Ramil (Portugal) for 2023 and found direct emission savings of 5,3 tCO2e in a 1 year monitoring period

Biodiversity measures were implemented on the surrounding site of Rodrigues’ factory by STRIX (impact assessment will be carried out at the end of 2024)

The Results from The Biodiversity Pilot at Ramil

Project Mission

Enhance and restore biodiversity in the area surrounding Ramil’s factory in Portugal.

Project Goal

Introduce a variety of native plant species to foster a thriving ecosystem that attracts more insects along with bird and bat life.

- 19 out of 23 biodiversity measured were achieved (including the plantation of native species with high nectar production, the installation of bat boxes, bird nests and bee hotels, and the creation of water points for insects and birds), resulting in an 83% success rate when it comes to Ramil’s on-site implementation (87% by summer 2024).

- While the overall gross area of the natural habitat remains similar in size, an increase in on-site biodiversity was noted, achieved through the plantations of various native flora species, the creation of extra micro-habitats and the adoption of organic farming practices.

- GANNI's Biodiversity Consultants, STRIX, notes that sustaining the implemented measures and monitoring the ecosystems over an extended period will be crucial to see a gradual but increasingly enhanced biodiversity surrounding Ramil's factory.

What we learned in 2023 is that when it comes to projects dedicated to protecting and restoring our natural ecosystems and biodiversity, continuous maintenance and a long-term perspective are key to achieving visible positive results. Additionally, the results may not always be as clear-cut and easily measurable as, for example, in the case of solar panel installations, where we can calculate emissions savings. Looking ahead to 2024, we will continue monitoring our biodiversity pilots, look into different methodologies and monitoring frameworks, and explore how to scale our work for the most meaningful impact.

GOAL 6

Develop a biodiversity strategy by 2023

We're bringing our goal to develop our own biodiversity strategy along with us into 2024. Initially, we aimed to use insights from our two biodiversity pilot projects to finalise the strategy by 2023. However, unexpected weather conditions in Portugal forced us to delay the biodiversity monitoring at Ramil and the implementation of biodiversity measures at Rodrigues. This led to an adjustment in our overall timeline.

In 2024, we'll capitalise on the initial results from Ramil, gain valuable insights from Rodrigues, and kick off an exciting project to better understand the impact of our supply chain on biodiversity using satellite data. Pulling together all these insights, we're aiming to roll out our biodiversity strategy in 2024.